INFRASTRUCTURE

Machinery Available

Machine

Machine

Machine

Machine

Machine

Machine

Film Machine

R&D Facility

PRINTING

ROTO GRAVURE PRINTING MACHINE

The top of the line, highly automated ELS/MLS rotogravure printing machine, particularly suited to top quality, medium to long run jobs. The technologically advanced expert PAC 4000 series with us features Mechanical/Electronic Line Shafting for high speed, high accuracy operations with Automatic register control and a sophisticated operator-friendly interface for effective production management.

Web width – up to 1100 mm

Speed – up to 350 m/min

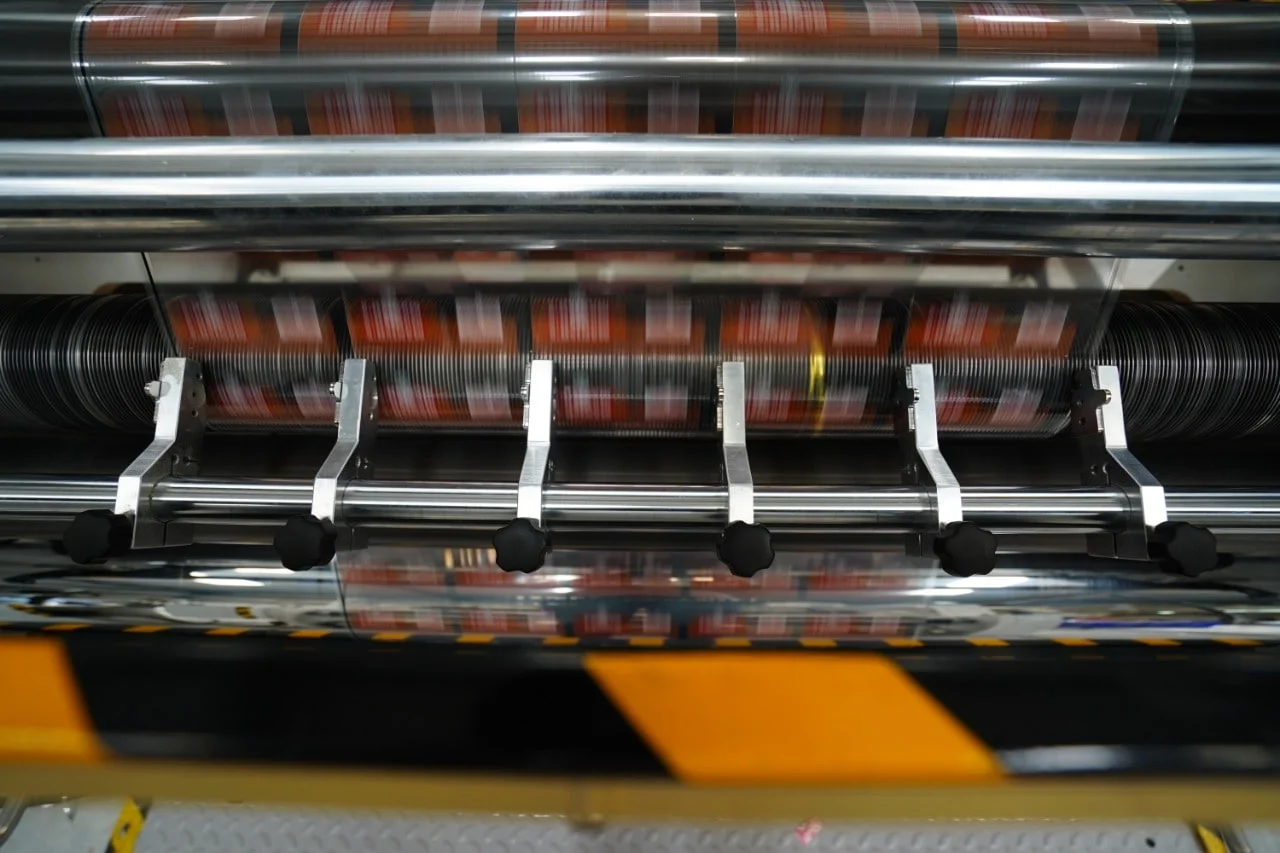

INSPECTION

INSPECTION MACHINE

Inspection is the most important process for flexible converters to ensure the defect-free to their customer. To ensure the removal of the defective material. This process ensures saving in wastage for downstream process & also prevent bad for high-speed Inspection. it stops upon a touch of a Defect button on user interface & reverses until the Defect positioned on the inspection table. This enhances the of inspection. This type of solution is economical & value for money for the customers.

Web width – up to 1300 mm

Speed – up to 500 m/min

LAMINATION

SOLVENT BASED AND FREE LAMINATION

By perfect integration of the new generation of electronics and ergonomically designed mechanical components, our machine is made to deliver optimum performance and productivity.

High productivity, easy operating, optimum energy consumption and ability to handle a wide range of laminating jobs are the key features.

Web width – up to 1100 mm

Speed – up to 350 m/min.

SLITTING

SLITTING MACHINE

Sealing is one of the main methods for bonding thermoplastics and this is precisely why sealability is a crucial feature of our packaging materials. In our laboratory, we test films with the HSG-C sealing machine. Each material is exposed to this check under specific temperature, time and pressure conditions. The strength of welded seals is measured in a similar fashion to tensile strength according to the GOST 14236 and ASTM 882 standards.

Web width – 40 to 1300 mm

Speed – up to 500 m/min.

POUCHING

POUCHING MACHINE

We have 19 pouching machines in-house to cater to the ever demanding market requirements of our valuable customers. This makes us a complete solution provider in one place. Our pouching capabilities include:

- Centre seal Pouch.

- Three sided seal Pouch.

- Standing pouch with zipper bag making

- Three-side-seal with zipper bag making

- Standing pouch bag making.

- Perforation Pouch making.

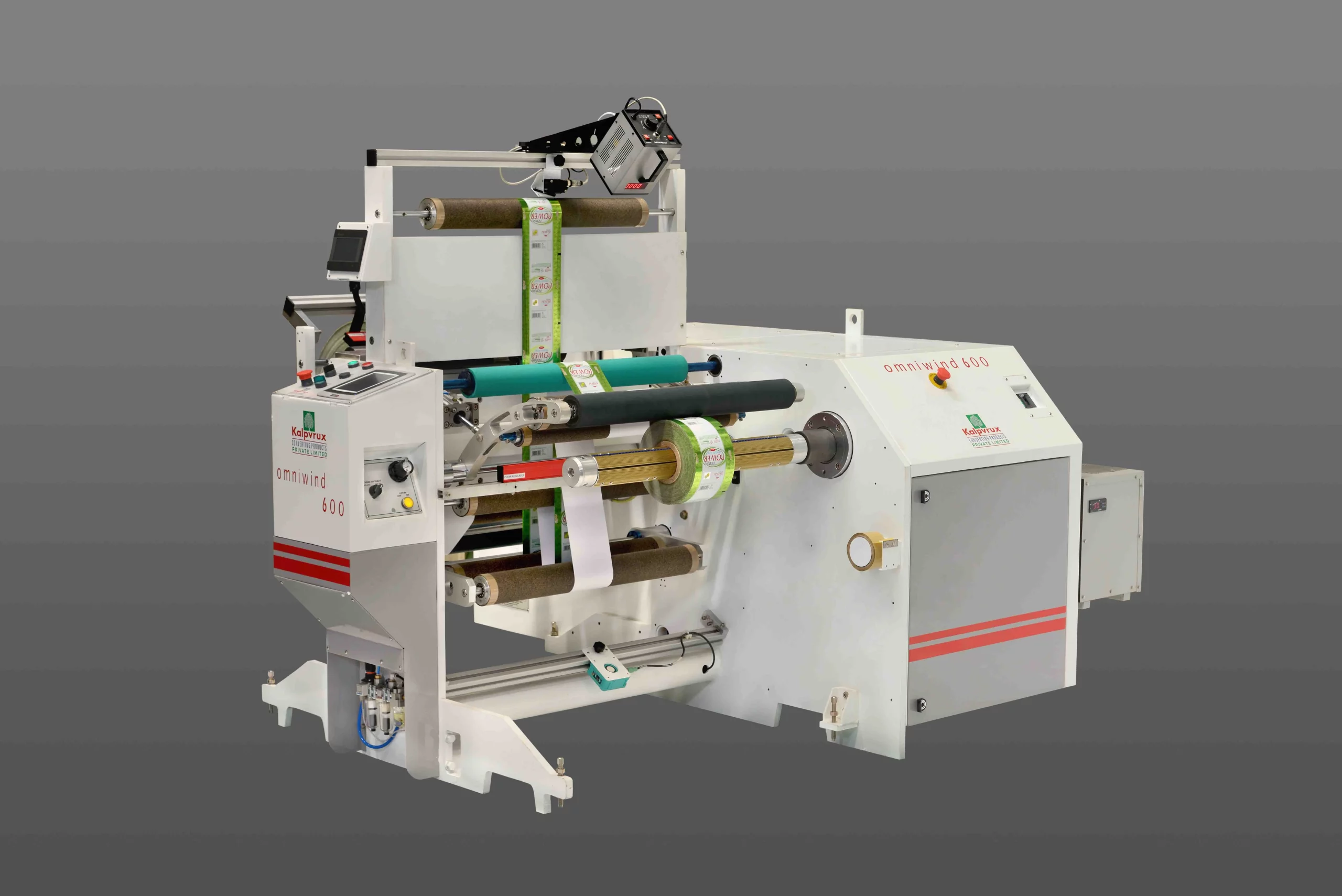

REWINDING

DOCTORING/COIL REWINDING MACHINES

In Flexible packaging industry, slitter operators and materials aren’t always perfect. Slitted rolls are sometimes wound with undesirable defects, resulting in a wasted role. We are equipped with high-performance reversible Doctoring Machine, that is ideal for rewinding of narrow slit finished reels and can reduce rewind times by more than 70-90 %, which help us to provide 100% defect free and perfect material to our customers.

Web width – up to 1300 mm

Speed – upto 350 m/min.

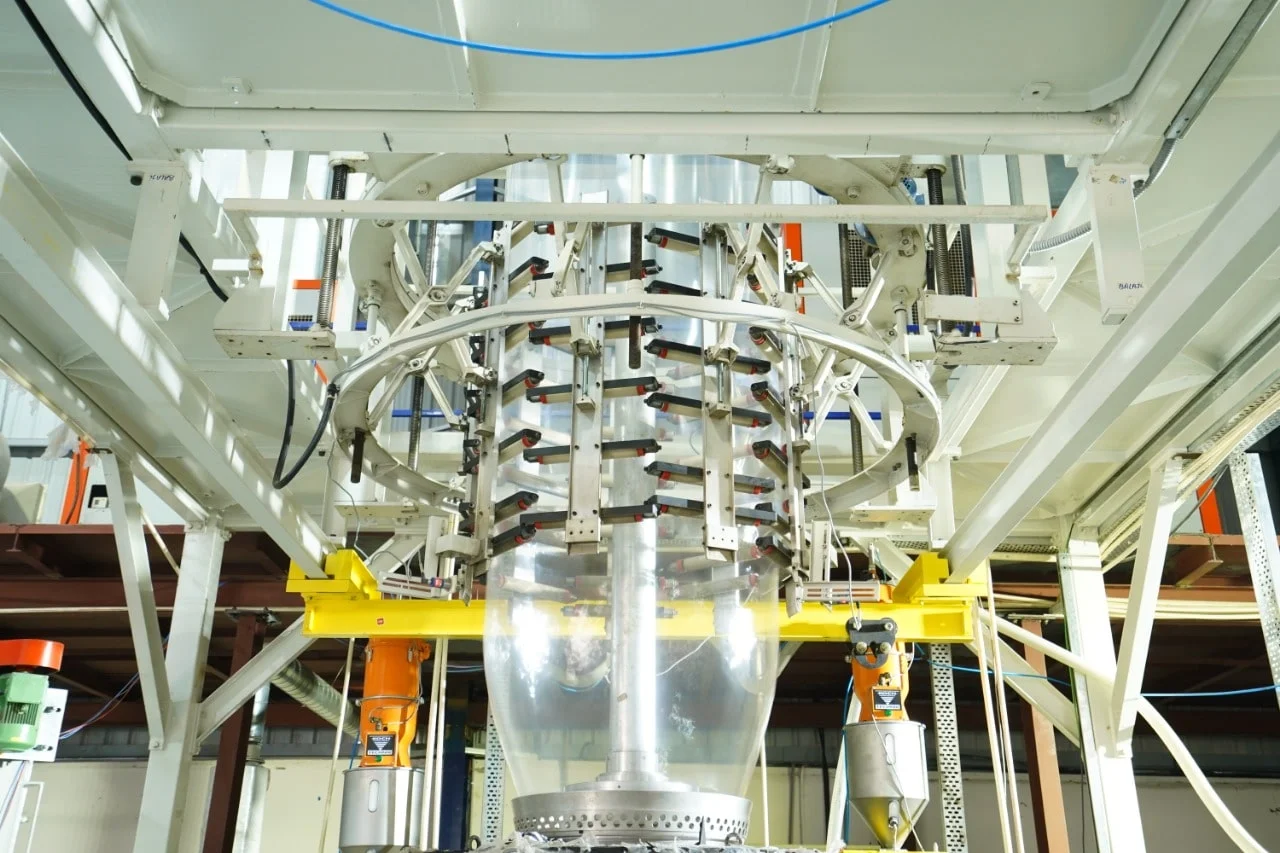

BLOWN FILM

MULTILAYER BLOWN FILM LINE

TRL has been catering to the rapidly growing needs of the flexible packaging industry. With the objective of meeting the new challenges faced by the market for improved film properties and cost optimisations, TRL has been in the forefront of bringing Multilayer Blown Film in its kitty with latest technology like Internal Bubble Cooling (IBC), Oscillating Haul-off and Advanced Winding Solutions to provide quality assurance and timely delivery to our customers.

LAB

LAB FACILITY

Over the past 15 years, TRL has equipment and highly skilled machine operators, and we manufacture flexible packaging materials under strict GMP conditions. Our products adhere to standards to meet the needs of our customers. to ensure product safety, integrity,, and the operational controls in the food packaging industry. We perform a number of rigorous quality test on our products, including:

- Product package compatibility testing

- Interlayer adhesion testing

- Puncture Resistance

- Tensile Resistance

- Seal strength testing

- Burst Testing

- Drop Testing

- Compression testing